How Does a Snugglebug Get Made?

Share

Ever wonder how your beloved stuffed animals come to life? It's a journey of creativity, precision, and a whole lot of fluff! Let's pull back the curtain on the enchanting world of stuffed animal creation, from the initial spark of an idea to the final stitch that makes a friend.

The Spark of Imagination: Designing the Perfect Plushie

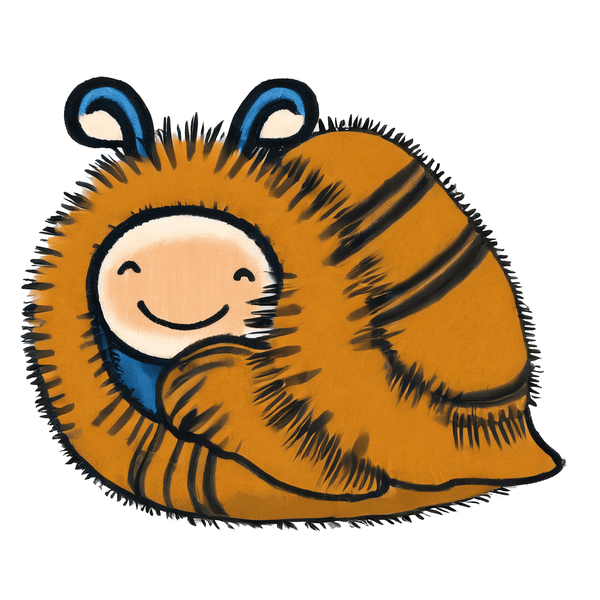

Every stuffed animal (including a Snugglebug) begins as a concept. We brainstorm ideas inspired by beloved endangered animals and add our signature whimsical and cartoonish twist.

-

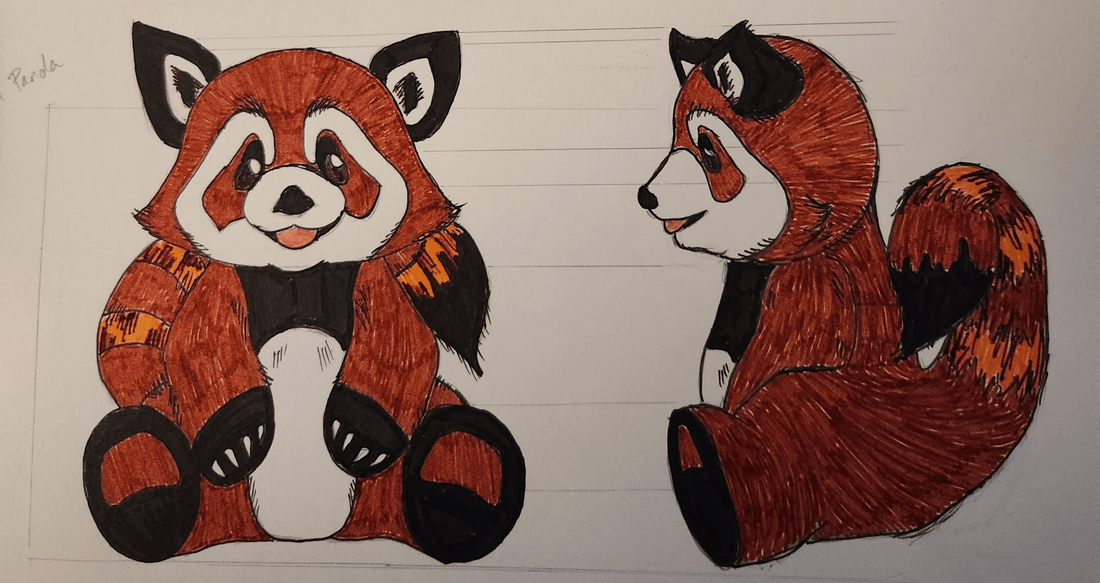

From Sketch to Blueprint: The journey starts with a simple sketch. This initial drawing captures the character's personality and key features. In today's world, many designers utilize computer-aided design (CAD) software to create 3D models, allowing for precise adjustments before a physical prototype is even made, but what we provide to our manufacturers is good, old fashioned hand drawings.

- A Star is Born: Once a design is finalized, it's translated into a detailed pattern. This pattern acts as a blueprint, with each piece meticulously planned to ensure a perfect fit during assembly. The first physical iteration of the stuffed animal is the prototype. This sample is crucial for evaluating the design, materials, and overall feel of the toy. It's a hands-on opportunity to make any necessary tweaks to the pattern or material choices to ensure the final product is both adorable and well-made.

The Building Blocks of a Buddy: Materials Matter

The heart of a huggable friend lies in its materials. The selection of fabrics and fillings is a critical step that determines the stuffed animal's softness, durability, and safety.

-

A Symphony of Softness (Common Fabrics):

- Plush: The classic, soft, and cuddly fabric most associated with stuffed animals.

- Fleece: Known for its warmth and durability, fleece comes in a variety of textures.

- Felt: Often used for smaller details and embellishments due to its non-fraying nature.

- Minky: An incredibly soft and luxurious fabric with a slight stretch, perfect for extra cuddly creations.

-

Faux Fur: Used to mimic the look and feel of real fur, adding a touch of realism to animal-inspired plushies.

-

What's Inside Counts (Types of Stuffing):

- Polyester Fiberfill: The most common stuffing, known for its softness, affordability, and hypoallergenic properties.

- Cotton: A natural and biodegradable option, though it can be denser than synthetic alternatives.

- Foam: Used to create a more structured or firm shape in certain parts of the toy.

- Plastic Pellets: Often added to the base or paws of a stuffed animal to provide weight and help it sit upright.

Bringing the Design to Life: The Art of Assembly

With the design perfected and materials selected, the manufacturing process begins, transforming individual pieces into a recognizable character.

- Precision Cutting: The fabric is carefully cut according to the pattern pieces. This can be done by hand for smaller batches or with the aid of machinery for mass production to ensure consistency.

- The Magic of Sewing: Skilled artisans or industrial sewing machines meticulously stitch the fabric pieces together. This is where the stuffed animal starts to take its three-dimensional form.

- The Finishing Touches: Details like eyes, noses, mouths, and other decorative elements are often added through embroidery. This can range from simple hand-stitching to intricate designs created by specialized machines. Appliqué, the technique of sewing smaller fabric pieces onto a larger one, is also used to add layers and visual interest.

- The Heart of the Plushie: Once sewn, the "skin" of the stuffed animal is turned right-side out and filled with the chosen stuffing. This is a crucial step to ensure the toy is perfectly plump and huggable.

- The Final Seam: The last opening is carefully sewn shut, often using a hidden stitch to create a seamless finish.

Ensuring a Lifetime of Love: Safety and Quality Control

Before a stuffed animal can be sent to its new home, it must undergo rigorous safety testing and quality checks to ensure it's a safe and durable companion for all ages.

-

Meeting the Standards: In the United States, stuffed animals must adhere to strict safety regulations set by the Consumer Product Safety Commission (CPSC) and the ASTM F963-17 standard for toy safety. These standards cover a wide range of potential hazards, from flammability to the makeup of the materials themselves. Snugglebug works with accredited, industry-leading third-party testing organizations to ensure our toys are as safe and durable as they can be, and provides information about these testing organizations on the Children's Product Certificate for each plush.

-

Key Safety Checks:

- Small Parts Test: Ensures that small components, like eyes or buttons, cannot be easily detached and become a choking hazard for young children.

- Flammability Test: Determines the fabric's resistance to fire.

- Seam Strength Test: Ensures the seams can withstand pulling and tugging without breaking.

-

Material Cleanliness: Verifies that the stuffing materials are clean and free from any harmful substances.

- The Final Inspection: Each finished stuffed animal is inspected for defects in sewing, embroidery, or overall construction. This final check ensures that only the highest-quality plushies reach a child's hands.

From a simple idea to a cherished friend, creating a stuffed animal is a thoughtful and intricate process. The next time you hug your favorite plush companion, you'll have a deeper appreciation for the artistry and care that went into bringing it to life.